AP 510

Black

ALUMAX

PVC WALL PANEL

Remove Protective Film in 45 days After Installation

WHY USE ALUMAX PVC WALL PANELS?

ALUMAX PVC foam wall panel (also called as wood/ marble veneer as per color features.) has a lot of benefits, including excellent thermal insulation, flexible and shapeable, high strength, outstanding durability, low water absorption, high corrosion resistance, and fire resistance,Clear and natural texture, wide range of style options. Due to these benefits, the material is ideal to fit different interior decorative requirements.

Because they’re so low maintenance, ALUMAX PVC Wall Panels are great for any interior wall. They handles high humidity levels, easy to clean, and will never become mouldy or gross.

Our Products

ALM602

ALM601

ALM613

ALM612

ALM604B

ALM604A

ALM607

ALM606

ALM605

ALM614

ALM608

Technical date sheet

| Type | Solid Board |

| Material | PVC with powder of CaCo3 |

| Film Coating | Hot film coating |

| Color | Hundreds(refer to color and pattern book) |

| Size | Width: 1.22m, Length: Customized (2.44m,2.6m,2.8m etc.) |

| Thickness | 5mm or 8mm |

| Density of Material | >0.60g/cm³ |

| Environmental Level | EO (Formaldehyde release 0.04mg/m³) |

| Fire Proof Level | B1 |

| Shrinkage Ratio | 0.2% (72 hours in ambient temperature 70℃) |

| Other properties | lmpact resistant, waterproof,moisture resistant, and easy to clean |

| Usage | Wall panel or Ceiling |

| Option Accessories | Aluminum moulding |

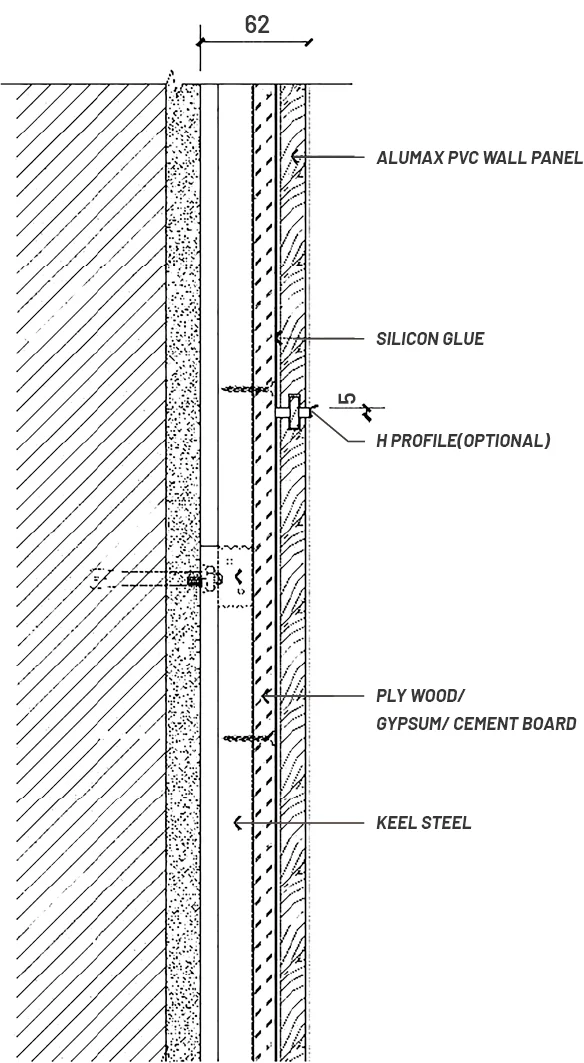

PROCESSING & INSTALL METHODS

Knife and Measuring tools

Measuring and cutting the board

Silicon Glue Adhesive foam

Fix the board to wall permanently

Double-side

Fixing the board on the wall in right positin

Plane

Cutting the edge of board in even

Cutting Machine

Cutting the board in right sizes

Trimming Machine

Notch the back of board, bend it in 90°

Heat Gun

Heating the back of the board to bend it in arc

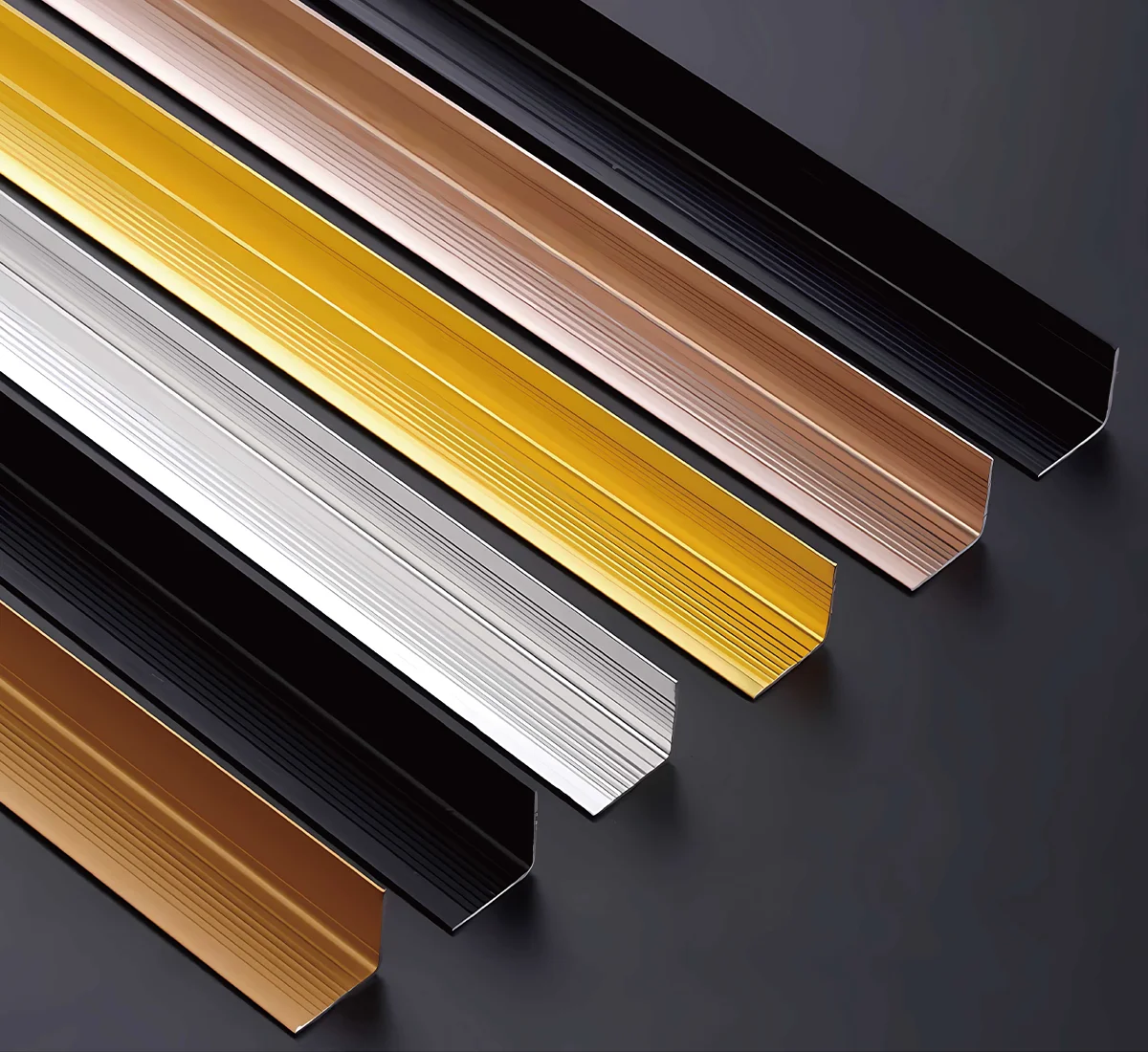

Aluminum Profile

Connect boards together

Construction

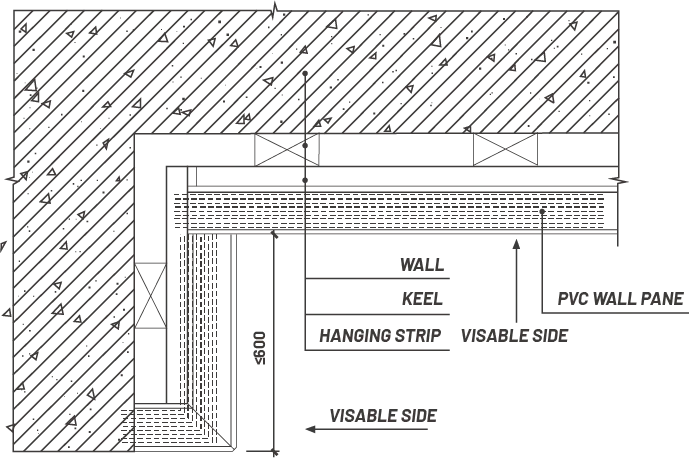

CORNER STRUCTURE

INNER CORDER STRUCTURE

ADHESIVE CONSTRUCTION PROCESS

Accessories